Your Custom Text Here

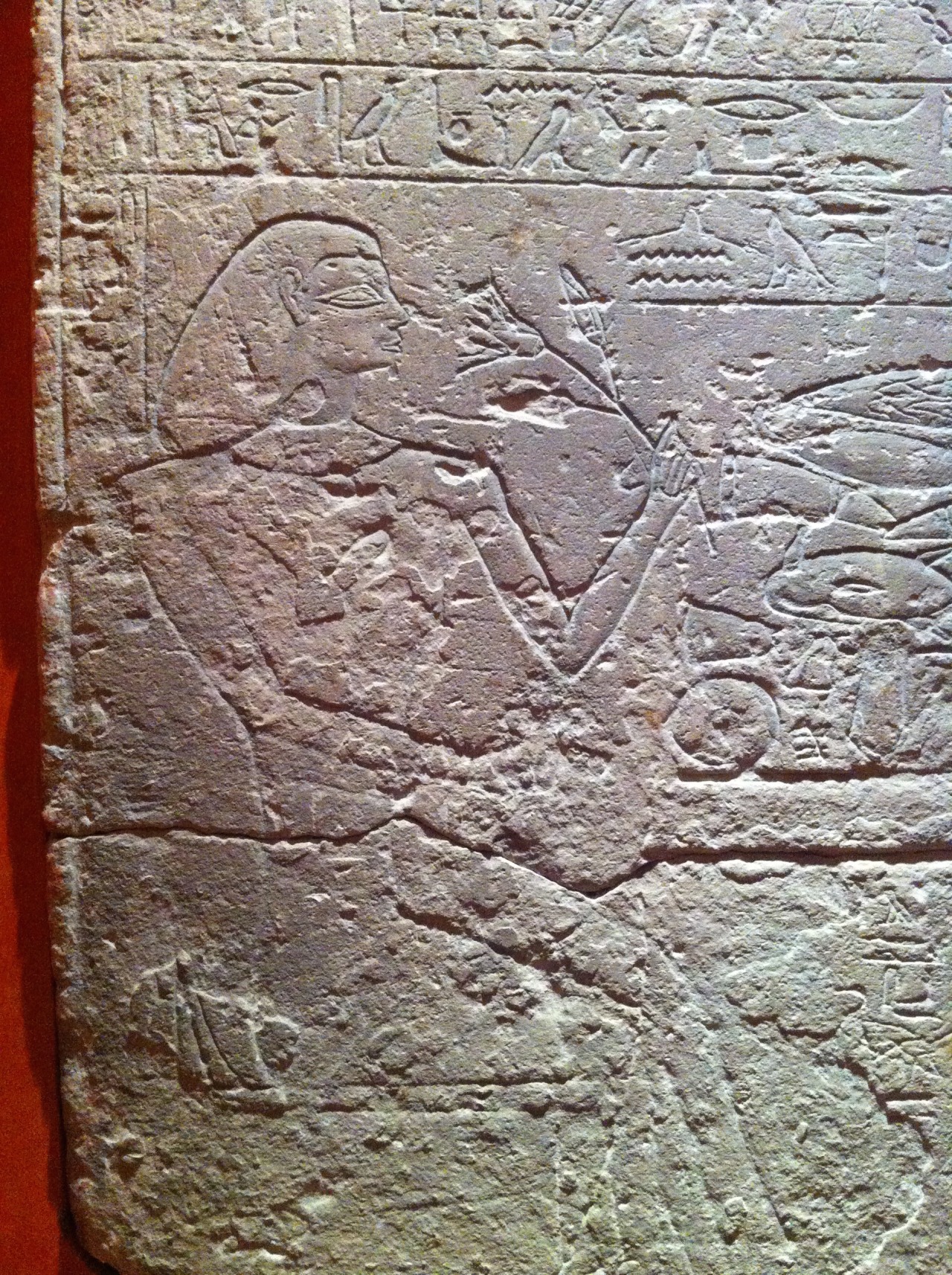

Fascinating Ancient Egyptian Mummies, Tomb goods and stone carvings were also on show at New Walk, Leicester

Research trip to New Walk Museum and Art Gallery, Leicester and some interesting ancient weaving styles on show

Research into ancient casting techniques

Research taken from Metropolitan Museum of Modern Art

“The ancient Greeks and Romans had a long history of making statuary in bronze. Literally thousands of images of gods and heroes, victorious athletes, statesmen, and philosophers filled temples and sanctuaries, and stood in the public areas of major cities. Over the course of more than a thousand years, Greek and Roman artists created hundreds of statue types whose influence on large-scale statuary from western Europe (and beyond) continues to the present day.

The earliest large-scale Greek bronze statues had very simple forms dictated by their technique of manufacture, known as sphyrelaton (literally, "hammer-driven”), in which parts of the statue are made separately of hammered sheets of metal and attached one to another with rivets. Frequently, these metal sheets were embellished by hammering the bronze over wooden forms in order to produce reliefs, or by incising designs using a technique called tracing.

By the late Archaic period (ca. 500–480 B.C.), sphyrelaton went out of use as a primary method when lost-wax casting became the major technique for producing bronze statuary. The lost-wax casting of bronze is achieved in three different ways: solid lost-wax casting, hollow lost-wax casting by the direct process, and hollow lost-wax casting by the indirect process. The first method, which is also the earliest and simplest process, calls for a model fashioned in solid wax. This model is surrounded with clay and then heated in order to remove the wax and harden the clay. Next, the mold is inverted and molten metal poured into it. When the metal cools, the bronze-smith breaks open the clay model to reveal a solid bronze reproduction.

Since the physical properties of bronze do not allow large solid casting, the use of solid wax models limited the founder to casting very small figures. To deal with this problem, the ancient Greeks adopted the process of hollow lost-wax casting to make large, freestanding bronze statues. Typically, large-scale sculpture was cast in several pieces, such as the head, torso, arms, and legs. In the direct process of hollow wax casting, the sculptor first builds up a clay core of the approximate size and shape of the intended statue. With large statues, an armature normally made of iron rods is used to help stabilize this core. The clay core is then coated with wax, and vents are added to facilitate the flow of molten metal and allow gases to escape, which ensures a uniform casting. Next the model is completely covered in a coarse outer layer of clay and then heated to remove all the wax, thereby creating a hollow matrix. The mold is reheated for a second, longer, period of time in order to harden the clay and burn out any wax residue. Once this is accomplished, the bronze-smith pours the molten metal into the mold until the entire matrix has been filled. When the bronze has cooled sufficiently, the mold is broken open and the bronze is ready for the finishing process.“

Exploring internal and external spaces of woven wax cont...

After discussing this with the foundry, one method that I would like to propose using would be to cast blocks of plaster on a set of stainless steel legs (using stainless steel legs ensures that they can withstand the heat of the casting). The plaster can be carved into the chosen shape or form to become a former for the wax. I would be working the wax directly onto the surface of the plaster in various weaving styles, the legs in the plaster allows the plaster block to be retained in the air, thus preventing the weight of the plaster crushing the wax. Once the weaving is complete the entire weave, plaster former and legs would go through the lost wax casting technique. Once the molten bronze is poured and cooled the foundry would cut a small section of the weaving to remove the plaster and legs, then the section of woven bronze would be replaced and welded back into place.

Removing problems of inflatables will open up many avenues for styles of cast work in a way that is non restrictive. This could lead into new fluid forms that are delicate, weaves would not have to be thick and they could have open areas. I can explore the internal space of a piece and expand into the exploration of negative and positive space. The possibilities are endless once the technical restrictions of an inflatable or cartable former are solved.

Watch this space for developments …..

Copper Allium Sculptures have been installed at Doddington Hall ready for their bi-annual sculpture in the garden exhibition which opens on the 2nd August

The Memorial sculpture is covered with little wooden petals, each one representing a baby, and in some cases two babies.

The sculpture is the main focus of the garden which features paved areas, Lavender beds, carved green Oak benches and box hedging. Leading you into the garden is winding woodland path lined with box hedging.

Sands Memorial Sculpture

The woven cocoon is now complete and in situ at the new Baby Memorial Garden in Markeaton, Derbyshire.

Its taken over 10,000ft of cane to weave the cocoon with one continuous chain stitch, and will become the basis of the memorial for families who have lost their babies during pregnancy or shortly after birth.